Toulouse, France, October 25, 2023 – Airbus Group SE (Paris: AIR) will renew the entire fleet of chartered vessels that transport aircraft subassemblies between production facilities in Europe and the United States with three modern, low-emission roll-on/roll-off vessels, supported by wind-assisted propulsion.

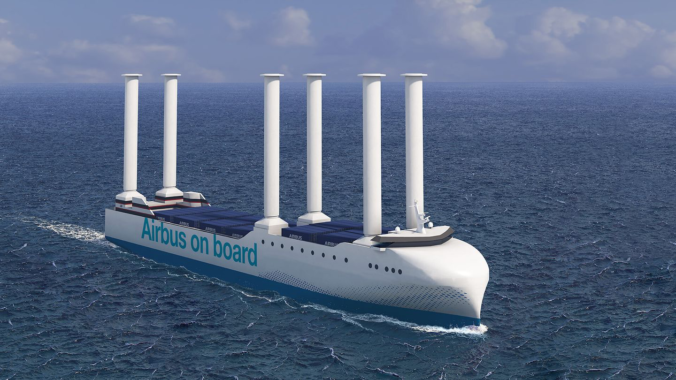

Airbus has commissioned shipowner Louis Dreyfus Armateurs to build, own and operate these new, highly efficient vessels that will enter into service from 2026. The new vessels will be powered by a combination of six Flettner rotors – large, rotating cylinders that generate lift thanks to the wind, propelling the ship forward – and two dual-fuel engines running on maritime diesel oil and e-methanol. Additionally, routing software will optimise the vessels’ journey across the Atlantic, maximising wind propulsion and avoiding drag caused by adverse ocean conditions.

The new fleet is expected to reduce average annual transatlantic CO2 emissions from 68,000 to 33,000 tonnes by 2030. This will contribute to Airbus’ commitment to reduce its overall industrial emissions by up to 63% by the end of the decade – compared to 2015 as baseline year.