– The 737-800BCF now has 134 orders and commitments

– Two additional freighter conversion lines are launched to meet strong demand in express traffic and e-commerce markets

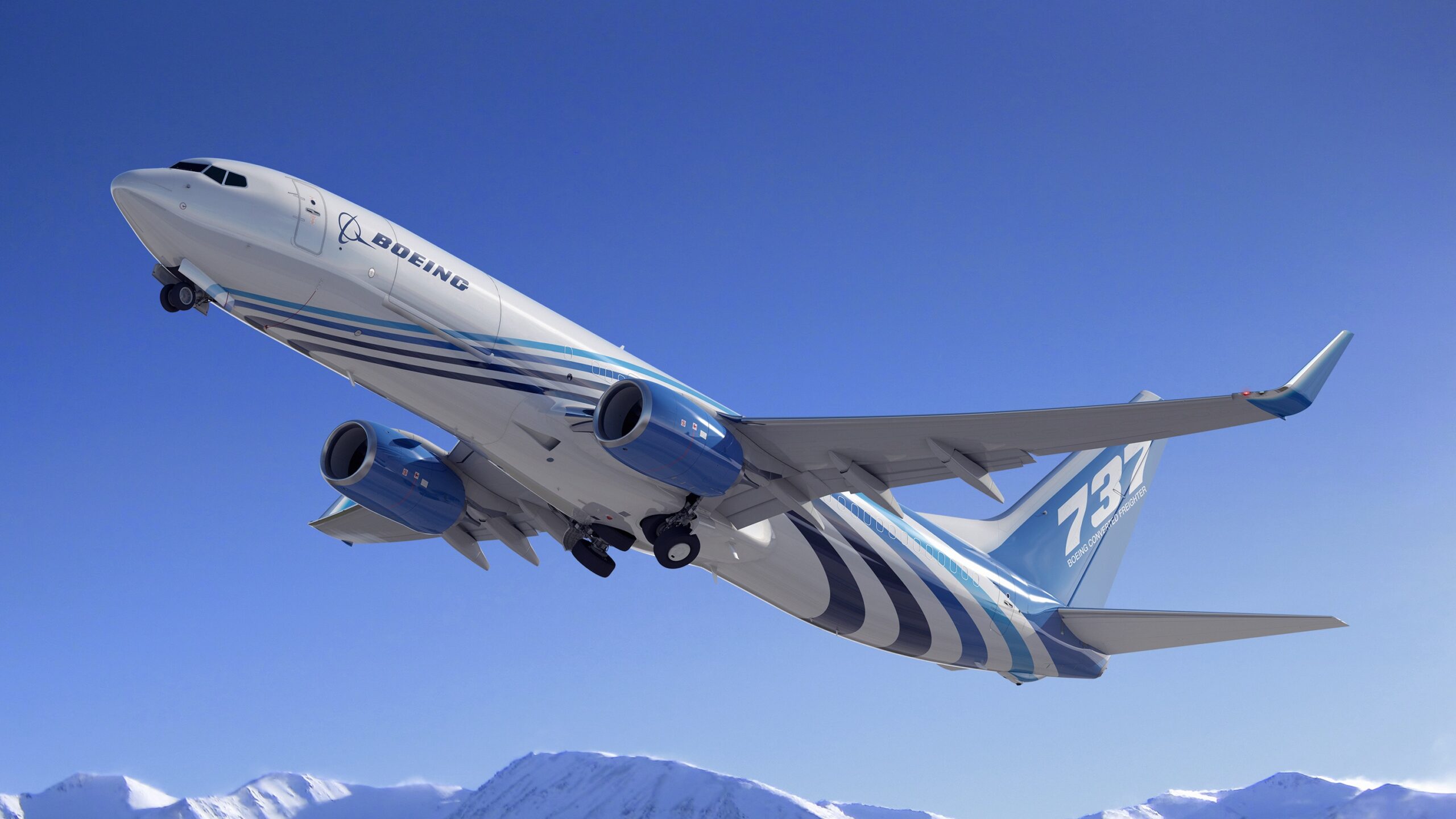

Boeing [NYSE: BA] today announced a firm order from an unidentified customer for two 737-800 Boeing Converted Freighters (BCF), as well as agreements to open additional conversion lines in Guangzhou, China, and Singapore to meet strong market demand.

Based on the popular Next-Generation 737, the 737-800BCF offers operators newer technology, lower fuel consumption and higher reliability than other standard-body freighters. Primarily used to carry express cargo on domestic or short-haul routes, the airplane is capable of carrying up to 23.9 tonnes (52,800 pounds) and flying up to 2,000 nautical miles (3,750 kilometers).

The 737-800BCF now has 134 orders and commitments.

The new 737-800BCF line at Guangzhou Aircraft Maintenance Engineering Company Limited (GAMECO) is scheduled to open in early 2021, marking the MRO’s second conversion line for the market-leading 737-800BCF. To date, Boeing has delivered 36 737-800BCF to more than 10 operators across four continents.

Boeing will also add a second conversion line for its widebody converted freighter, the 767-300BCF, at ST Engineering’s facility in Singapore. The second line is scheduled to open later this year.

The world’s most efficient freighter in its class, the Boeing 767 freighter family offers the lowest operating costs per trip and allows airlines to develop new opportunities in the long-haul, regional and feeder markets. The 767-300BCF has virtually the same cargo capability as the 767-300F production freighter with up to 56.5 tonnes (124,600 pounds) of payload and flying up to 3,350 nautical miles (6,190 kilometers).

The Boeing freighter family, which includes production and converted freighters, provides more than 90 percent of the world’s freighter capacity, offering an unmatched selection of capacity and capability with superior economics in every freighter size.