- With parts from nearly 250 suppliers, Alstom trainset production creates 1,300 new jobs

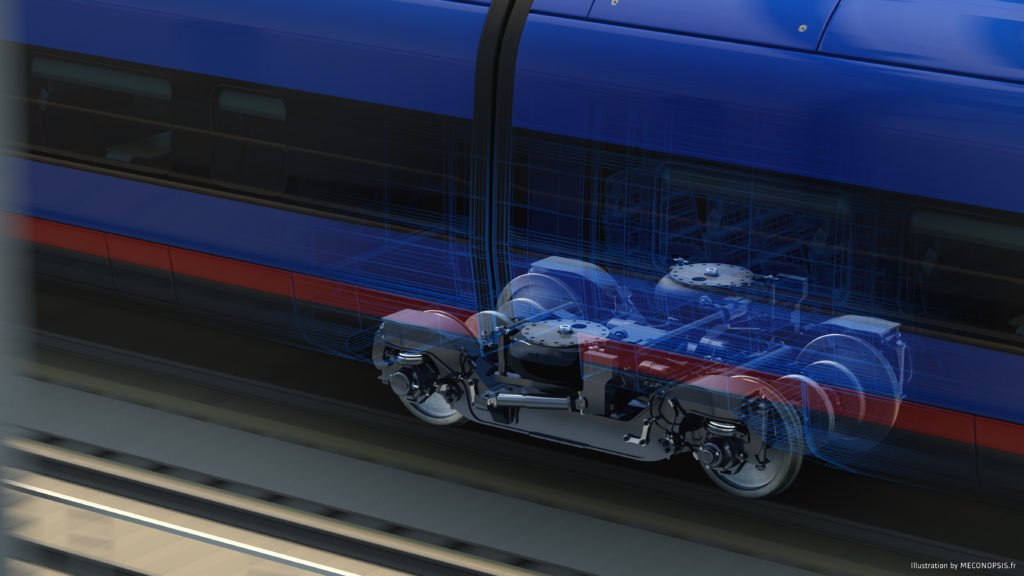

HARVEY, Ill. – The Amtrak partnership with Alstom to produce the next generation of Acela trains to move customers at higher speeds and more comfort between Boston and Washington is also boosting businesses nationwide. Today, Amtrak and Alstom thanked workers at LB Steel in Illinois for building wheel assemblies (known as “bogies” or “trucks”) and other components.

“While these new trains will provide world-class accommodations for customers traveling in the Northeast, this production will benefit communities across the country by creating jobs and stimulating local economies,” said Amtrak Executive Vice President Roger Harris, who led the visit to the factory south of Chicago. “The fastest trains in the hemisphere – at speeds up to 160 mph – will ride on the work done here in Harvey at LB Steel.”

Alstom is using parts manufactured by nearly 250 suppliers in 27 states, with 95 percent of the components produced domestically. More than 1,300 new jobs will be generated in nearly 90 communities across the United States to support production, including the creation of new, sustainable, high-tech, engineering and manufacturing jobs in New York.

“We are proud to have been selected by Amtrak, not only to design and build the new Avelia Liberty high speed trainsets, but also to provide long-term technical support, and supply spare components and parts for the maintenance of the new trains.,” said Michael MacDonald, Site Managing Director for Alstom in Hornell, N.Y., who also participated in the news event south of Chicago. “Alstom is partnering with suppliers across the country for this project, and the emergence of a high-speed rail manufacturing industry here in the U.S. is becoming a reality.”

The trains are being produced at Alstom’s Hornell facility, which is undergoing a massive investment and transformation to build the 28 high-speed trainsets for Amtrak. One of three new structures has been built to accommodate fleet manufacturing and testing and a new bridge has been built to extend the site’s current test track to accommodate higher speeds.

The new trains are scheduled to enter service in the Northeast Corridor in 2021 and will accommodate nearly 25 percent more customers while continuing the spacious, high-end comfort of the current Acela service that customers enjoy today. Each train will feature modern amenities such as improved Wi-Fi access, personal outlets, USB ports and adjustable reading lights.

The new Acela trains are part of an Amtrak plan to modernize and upgrade our fleet. Last year, Amtrak refreshed the interiors of the current Acela trains and Amfleet I railcars and announced plans to acquire 75 new locomotives for Amtrak’s long distance and state-sponsored services. This year, Amtrak performed similar work on Amfleet II railcars and announced plans to start next year to refresh Superliner cars used on long distance services. Refreshing of Horizon railcars in the Amtrak MidwestSM network is also now underway with state partner support.