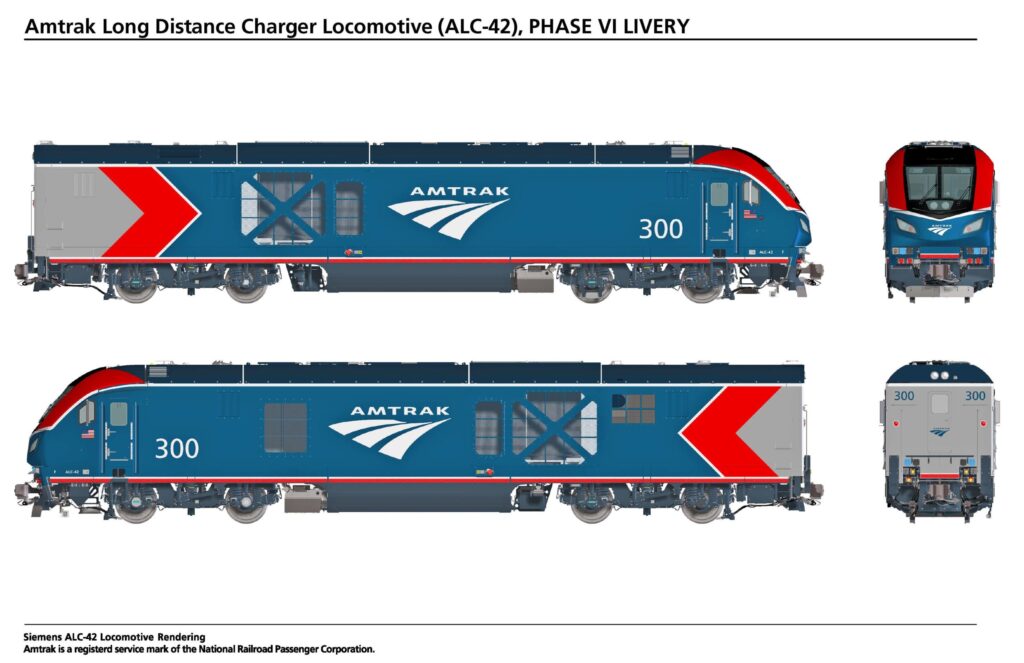

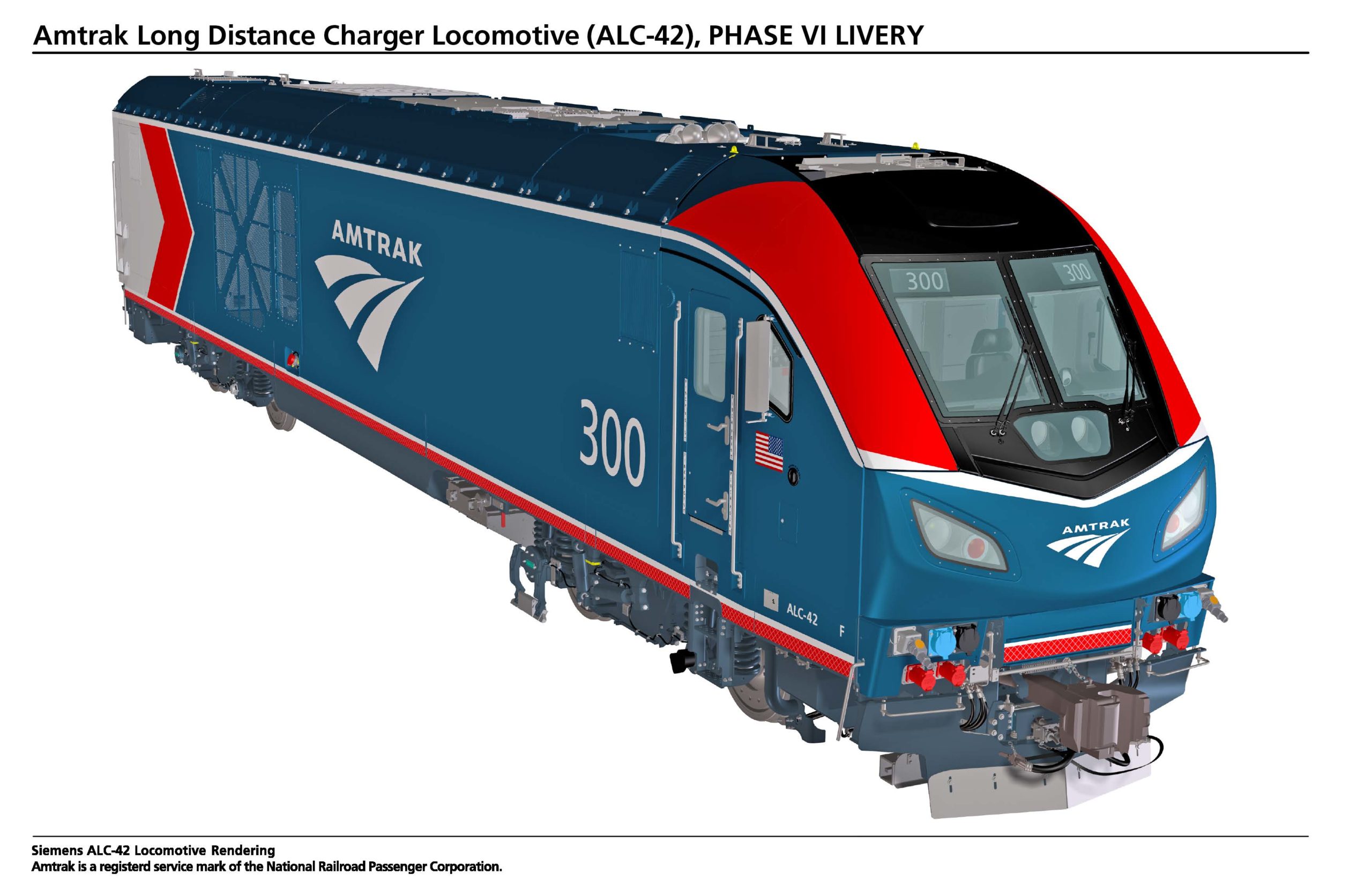

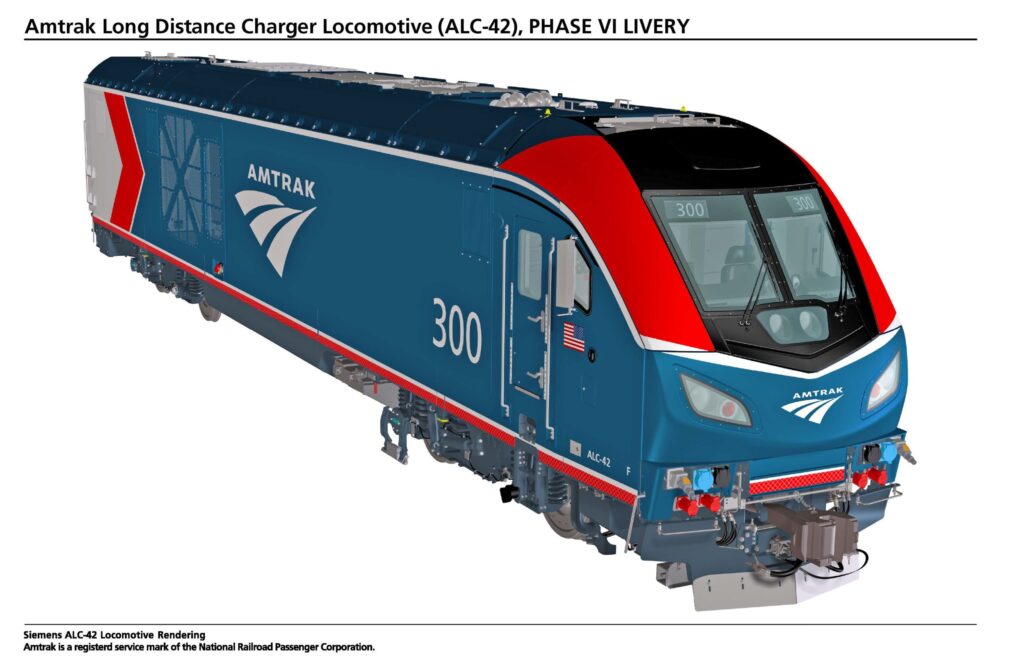

Amtrak today released renderings and other information about the first of the diesel-electric locomotives that will replace the current fleet on the National Network, including all long distance and many state-sponsored routes.

Five of the first six locomotives will have this version of our current Phase VI paint scheme (a “livery” in trade terms) and one will be painted to recognize next year’s 50th anniversary of the inauguration of Amtrak service. A final livery will be unveiled later as part of a fleet-wide plan.

The ALC-42 series was developed by Amtrak with Siemens Mobility and is equipped with the latest safety systems, including Positive Train Control and Crash Energy Management. They have Alternating Current Propulsion for a maximum speed of 125 mph. The 16-cylinder Cummins QSK95 engine has Tier 4 Emissions Technology to reduce nitrogen oxide by more than 89 percent and particulate matter by 95 percent, while providing a savings in diesel fuel consumption and reaching Amtrak Sustainability goals.

The initial order of 75 new locomotives was first announced by Amtrak in December 2018, with deliveries expected through 2024. Amtrak also has a provision to order additional ALC-42 locomotives.

They are similar to the SC-44 locomotives purchased by some state agencies and operated by Amtrak, but have greater fuel capacity for longer routes and increased Head End Power generating capacity for bigger trains. A multitude of other upgrades will also lead to longer maintenance intervals. The front of the ALC-42 locomotive will serve as a “new face of Amtrak” in much of the U.S. and is designed to enhance safety, aesthetics and to simplify repairs.

The new locomotives are designated as ALC-42 for “Amtrak Long-distance Charger, 4,200-horsepower” and are in production in Sacramento, Calif. They will primarily replace Amtrak P40 and P42 diesel-electric locomotives. Although modern when bought in the 90s, the P-series locomotives have been intensively used for more than 25 years, lack up to date technology and do not achieve Tier 4 emissions standards.

Amtrak is purchasing the new locomotives through available funds and fulfills “Buy American” provisions. Siemens Mobility has suppliers across the United States to support locomotive production, including Cummins, which manufactures the diesel engines in Seymour, Indiana.

These new locomotives are part of Amtrak’s long-term planned series of improvements for fleet, infrastructure and stations, including new Acela trainsets now undergoing tests to begin service next year. Improvements are ongoing at New York Penn Station and Moynihan Train Hall, in addition to expanded development of the major stations at Washington, D.C., Baltimore, Philadelphia and Chicago.