Saint-Cloud, France, May 06, 2021 – Dassault Aviation today announced an all-new Falcon jet that will deliver a level of comfort, versatility and technology unmatched by any purpose-built business jet. Featuring a range of 7,500 nautical miles, the Falcon 10X will fly nonstop from New York to Shanghai, Los Angeles to Sydney, Hong Kong to New York or Paris to Santiago. Top speed will be Mach 0.925.

The Falcon 10X is scheduled to enter service at the end of 2025.

The 10X will have the biggest and most comfortable cabin on the market and offer greater modularity than any other aircraft in its class, with a selection of multiple interior configurations. The 10X is large enough to accommodate four cabin zones of equal length but owners can configure their cabin to create a truly customized interior, including for example, an expanded dining/conference area, a dedicated entertainment area with a large-screen monitor, a private stateroom with a queen-size bed or an enlarged master suite with a private stand-up shower.

The 10X will have a cabin cross section larger than some regional jets. Its cabin will be 6-feet, 8-inches (2.03 m) tall and 9 feet, 1 inch wide (2.77 m). That will make it almost 8 inches (20 cm) wider and 2 inches (5 cm) taller than the widest and tallest purpose-built business jet flying today.

Pressurization will also be the best on the market, with passengers experiencing a 3,000-foot cabin pressure altitude while flying at 41,000 feet. A next-generation filtration system will provide 100-percent pure air. The aircraft will be at least as quiet as the Falcon 8X, currently the quietest business jet in service.

The 10X will feature an entirely new fuselage with extra-large windows—nearly 50 percent larger than those on the Falcon 8X. Thirty-eight windows will line the fuselage making for the brightest cabin in business aviation.

The high-speed wing will be made of carbon fiber composites for maximum strength, reduced weight and minimum drag. Tailored for speed and efficiency, the very-high aspect ratio wing will be equipped with advanced, retractable high-lift devices offering superior maneuverability at low approach speeds.

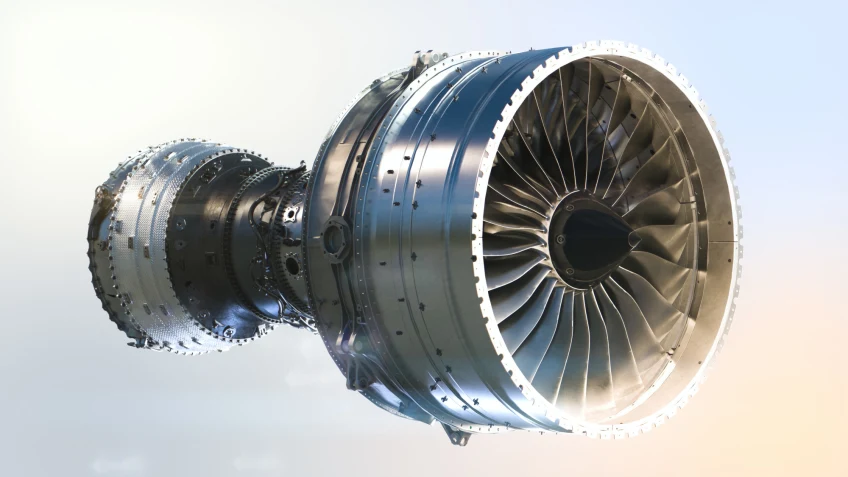

The twin-engine aircraft will be powered by business aviation’s most advanced and efficient engine, the in-development Rolls Royce Pearl® 10X. The 10X is the latest, largest and most powerful version of the Pearl series, delivering more than 18,000 pounds of thrust.

The Falcon 10X’s flight deck will set a new standard in intuitive design, with touch screens throughout the cockpit. A next-generation Digital Flight Control System, derived directly from Dassault’s latest military technology, will provide an unprecedented level of flying precision and protection, including a revolutionary, new single-button recovery mode.

A single smart throttle will serve as the primary power control, connecting both engines to the Digital Flight Control System which will automatically manage the power of each engine as needed in different flight scenarios.

Thanks to Dassault’s breakthrough FalconEye® combined vision system—the first to offer both enhanced and synthetic vision capabilities—combined with dual HUDs able to serve as primary flight displays, the 10X will be capable of operating in essentially zero ceiling/visibility conditions.