WICHITA, Kansas, August 26, 2021 – Textron Aviation today announced it successfully completed initial ground engine runs on the prototype Beechcraft Denali single-engine turboprop powered by GE Aviation’s new advanced Catalyst engine. The ground engine runs, which took place at Textron Aviation’s west campus in Wichita, Kansas, verified the functionality of the fuel system and engine, as well as the interface with the avionics and electrical systems. The testing moves the clean-sheet design aircraft closer to its milestone first flight, which is anticipated by the end of the year.

The Beechcraft Denali is designed and manufactured by Textron Aviation, a Textron Incorporated (NYSE: TXT) company.

GE Aviation’ Catalyst engine has completed over 2,450 hours of testing and is prepping for a first flight on its Beechcraft King Air flying test bed. The Catalyst engine is a more environmentally friendly engine that burns less fuel than older turboprop technologies. The engine can also use sustainable aviation fuel, which results in lower emissions. The 1,300 shaft horsepower (SHP)-rated turboprop engine eases pilot workload with its single-lever power and propeller control. The Full Authority Digital Engine Controlled (FADEC) engine provides trend monitoring, which allows for on-condition maintenance with no mid-life Hot Section Inspection required.

The Beechcraft Denali development program has achieved several important milestones in recent months. Earlier this summer, GE Aviation Catalyst engine was installed on the Beechcraft Denali prototype airframe and the aircraft was powered on for the first time. Two other Denali flight test articles are also in development. Three additional ground test articles will be used for the airframe static and fatigue tests, and for cabin interior development and testing. The company anticipates certification for the Denali in 2023.

Technological advances

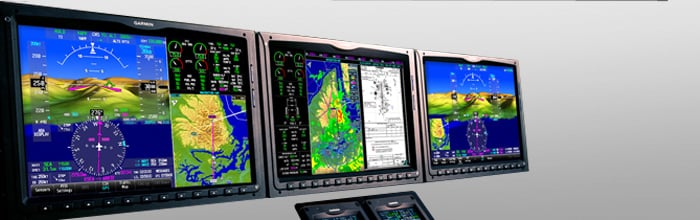

The Denali cockpit features the Garmin (NASDAQ: GRMN) G3000 intuitive avionics suite featuring high-resolution screens and touchscreen controllers. An integrated Garmin autothrottle is now a standard feature, which interfaces with the Automatic Flight Control System (AFCS) and Flight Management System (FMS) to provide easy speed control throughout all regimes of flight from takeoff to touchdown.

Other standard G3000 features include a 10-inch weather radar, Terrain Awareness Warning System (TAWS-B), and dual transponders with automatic dependent surveillance-broadcast (ADS-B) capabilities, which are compliant with the latest air traffic control requirements.

The aircraft is equipped with McCauley’s new 105-inch diameter composite, 5-blade, constant speed propeller, which is full feathering with reversible pitch and ice protection. The propeller will undergo a series of certification tests, and several are already underway.

Class-leading passenger experience

The Beechcraft Denali’s flat floor cabin is designed to be the largest in its segment and offers the versatility to easily convert between passenger and cargo configurations. The Denali cabin features a standard seating configuration of six individual reclining seats and offers a nine-place high density seating option.

The aircraft boasts a digital pressurization system maintaining a 6,000-foot cabin altitude at a service ceiling of 30,000 feet. The Denali also offers passengers the convenience of adjusting the cabin temperature and airflow from a climate-control switch panel located on the cabin sidewall.

Denali customers will also enjoy large cabin windows, interior LED lighting, a forward refreshment cabinet and an in-flight accessible baggage compartment. An optional externally serviceable belted lavatory with pocket door enclosure that is located in the rear of the cabin is also available.