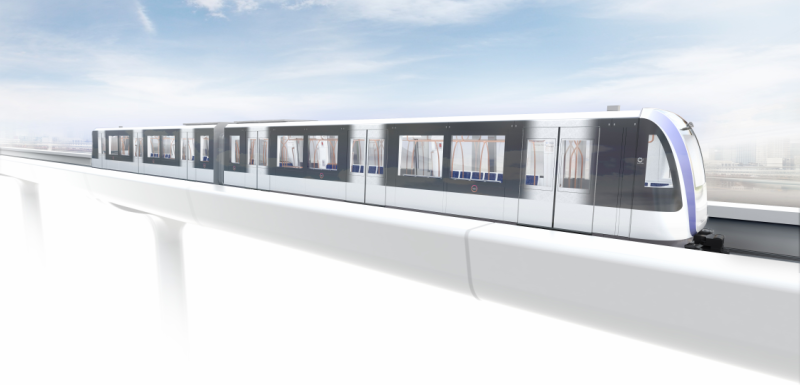

Alstom consortium picked to deliver Dominican Republic’s first monorail system

August 28, 2023 - Alstom (OTC: ALSMY), a global leader in smart and sustainable mobility, announces that the Consortium SIF (led by Alstom and including Sofratesa) has been selected by Fideicomiso para el Desarrollo del Sistema de Transporte…