Dallas, Texas, February, 2024 – Southwest Airlines Co. (NYSE: LUV) is celebrating the completion of a multi-year, $100 million project, which nearly doubles the size of the airline’s maintenance hangar at Phoenix Sky Harbor. The 90,000-square foot expansion adds three new aircraft bays to the facility, allowing the airline to work on up to five aircraft simultaneously and brings more maintenance shops to support the nearly 500 Southwest® Technical Operations Employees based at Sky Harbor. The project also included a larger facility for members of the airline’s Provisioning and Ground Support Equipment Maintenance Teams that opened in 2020.

The expanded hangar has also achieved Leadership in Energy and Environmental Design (LEED) Silver certification. The expansion incorporated sustainable design features including the use of recycled content in over 30% of the building materials; the installation of high-reflectance roof and surrounding paving materials to reduce heat island effect; and the selection of building products from manufacturers with verified environmental performance.

Southwest Airlines® first opened a Technical Operations base at Sky Harbor in 1986. In 1993, the airline moved into a new maintenance hangar facility to support its growth throughout the western half of the United States. Today, the carrier’s Phoenix-based Technical Operations Teams accept new aircraft deliveries to prepare them to enter revenue service and maintain aircraft as part of daily and scheduled maintenance programs.

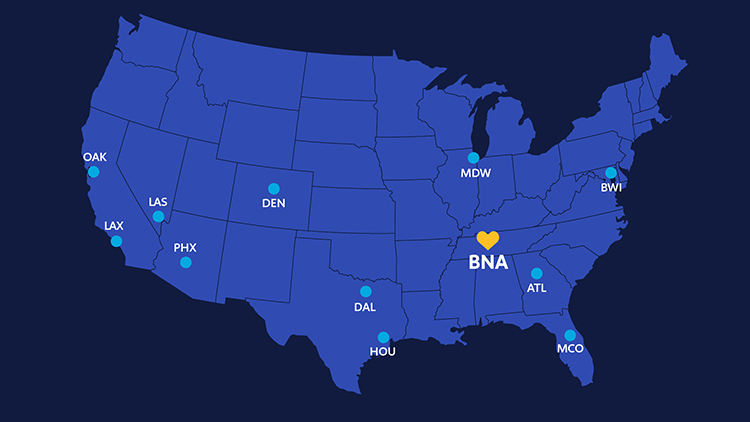

In addition to Phoenix, Southwest operates hangar facilities in Atlanta, Chicago (Midway), Dallas (Love Field), Denver, Houston (Hobby), and Orlando. Construction is underway on a new hangar facility at Baltimore/Washington International Airport, which is anticipated to open in 2025.

Forward-Looking Statements

This press release may contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, including expected delivery dates. Such statements are based on current expectations and projections about our future results, prospects and opportunities and are not guarantees of future performance. Such statements will not be updated unless required by law. Actual results and performance may differ materially from those expressed or forecasted in forward-looking statements due to a number of factors, including those discussed in our filings with the Securities and Exchange Commission.