Aerospace Boating News Business News Cargo News Economic News Economy News European News Finance News German International News Marine Ocean News Maritime News Railroad Railroad News stock stock news transport Transportation Transportation News

Rolls-Royce Signs Agreement to Sell Bergen Engines to TMH Group

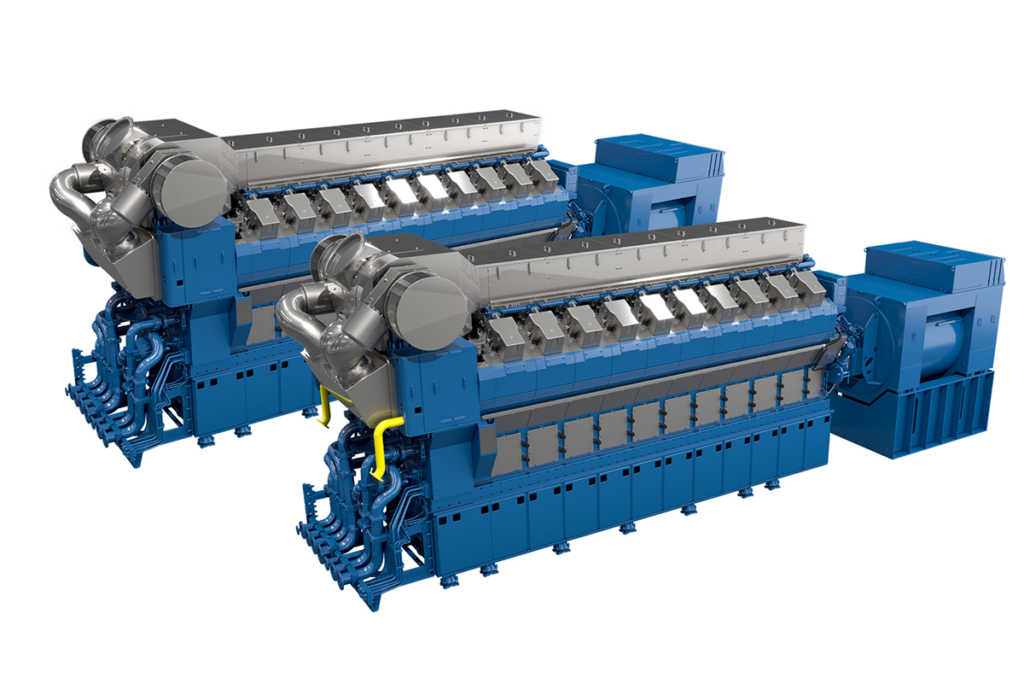

Rolls-Royce has signed an agreement to sell the Bergen Engines medium speed gas and diesel engines business to TMH International, the international branch of TMH Group, for net proceeds of approximately EUR 150m. TMH Group,…