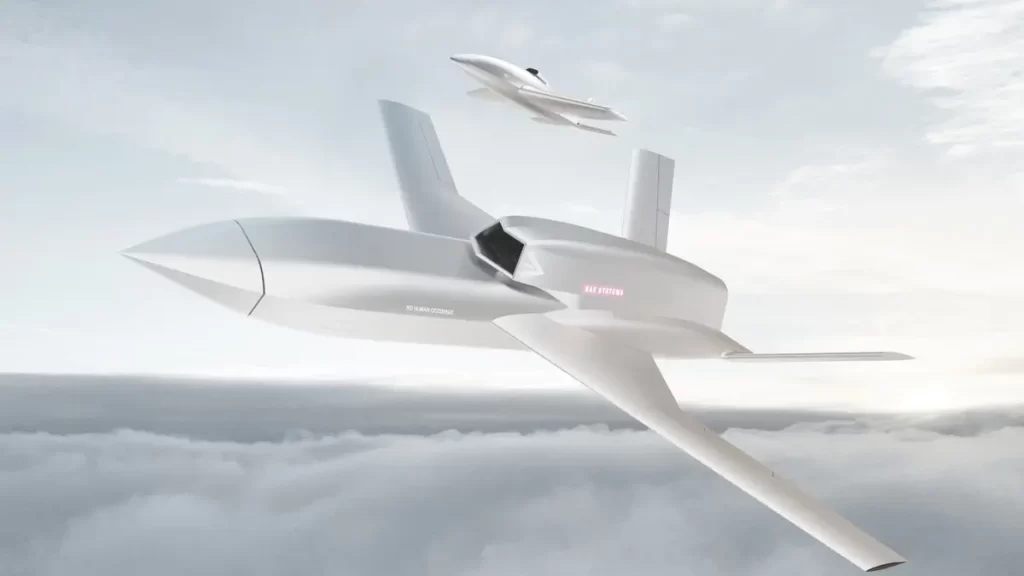

BAE Systems acquires Malloy Aeronautics

BAE Systems has acquired Malloy Aeronautics – a leading company in innovative heavy lift drone and aeronautical technologies. Malloy Aeronautics designs and supplies all-electric uncrewed aerial systems (UAS) to both civil and military customers. Their range…