Rolls-Royce (LSE: RR.L) announced today that following a successful equity raise, the Rolls-Royce Small Modular Reactor (SMR) business has today been established, to bring forward and deliver at scale the next generation of low cost, low carbon nuclear power technology.

Rolls-Royce Group, BNF Resources UK Limited and Exelon Generation Limited will invest £195m across a period of around three years. The funding will enable the business to secure grant funding of £210 million from UK Research and Innovation funding, first announced by the UK Prime Minister in ‘The Ten Point Plan for a Green Industrial Revolution’. Today’s announcement is another step towards the delivery of the Government’s net zero strategy and its 10-point plan.

The business, which will continue to seek further investment, will now proceed rapidly with a range of parallel delivery activities, including entry to the UK Generic Design Assessment (GDA) process and identifying sites for the factories which will manufacture the modules that enable on-site assembly of the power plants. Discussions will also continue with the UK Government on identifying the delivery models that will enable long-term investment in this vital, net-zero enabling technology. Rolls-Royce SMR is engaging with export customers across many continents who need this technology to meet their own net zero commitments.

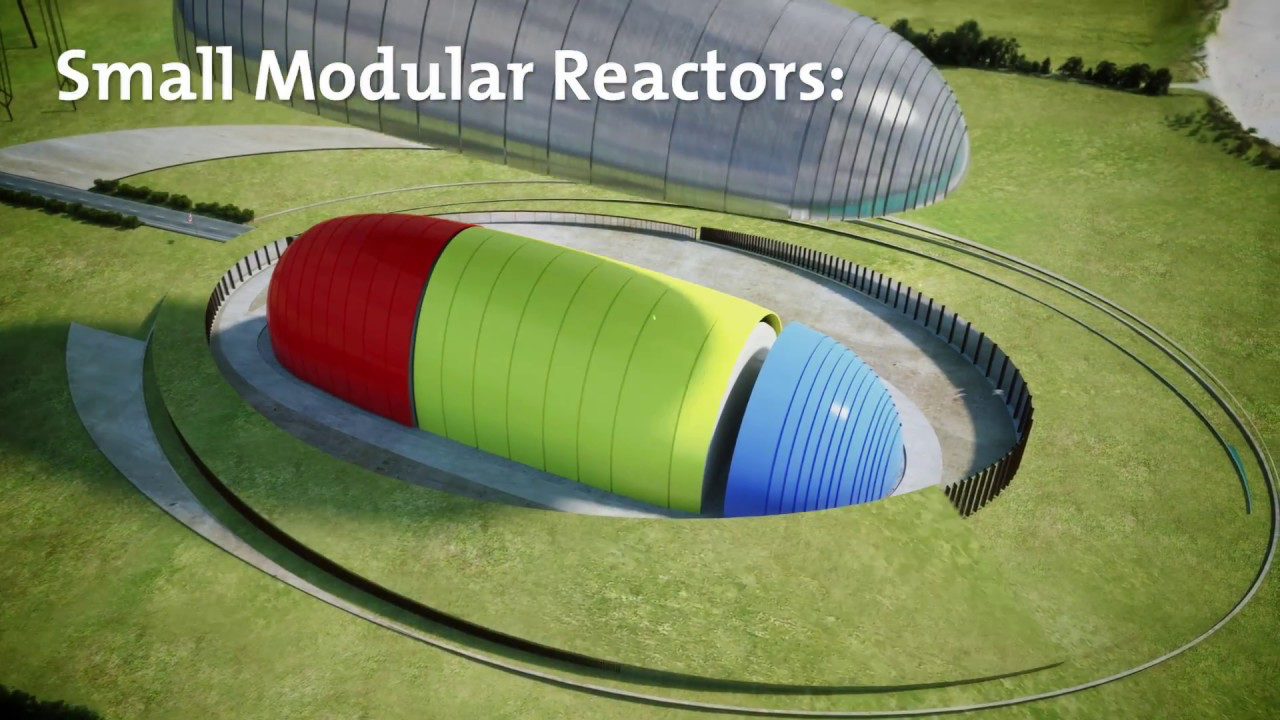

Rolls-Royce SMR is using proven nuclear technology, coupled with a unique factory-made module manufacturing and on-site assembly system, to harness decades of British engineering, design and manufacturing knowhow. It brings together the best of UK industry to ensure a decarbonisation solution that will be available to the UK grid in the early 2030s. The potential for this to be a leading global export for the UK is unprecedented.

Nine-tenths of an individual Rolls-Royce SMR power plant will be built or assembled in factory conditions and around 80% could be delivered by a UK supply chain – a unique offering in energy infrastructure in the UK. Much of the venture’s investment is expected to be focused in the North of the UK, where there is significant existing nuclear expertise

A single Rolls-Royce SMR power station will occupy the footprint of two football pitches and power approximately one million homes. It can support both on-grid electricity and a range of off-grid clean energy solutions, enabling the decarbonisation of industrial processes and the production of clean fuels, such as sustainable aviation fuels (SAF) and green hydrogen, to support the energy transition in the wider heat and transportation sectors.