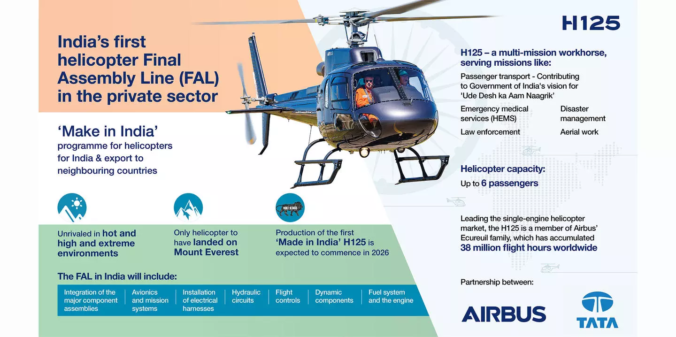

New Delhi, India, January 26, 2024 – In a major boost to ‘Make in India’, Airbus Group SE (Paris: AIR) Helicopters has announced that it is partnering with the Tata Group to establish a Final Assembly Line (FAL) for helicopters in the country. The FAL will produce Airbus’ best-selling H125 helicopter from its civil range for India and export to some of the neighbouring countries.

The FAL will be the first instance of the private sector setting up a helicopter manufacturing facility in India, providing a major boost to the Government of India’s ‘AatmaNirbhar Bharat’ (self-reliant India) programme. Under this partnership, Tata Advanced Systems Limited (TASL), a subsidiary of Tata Group, will set up the facility along with Airbus Helicopters.

The announcement was made during the two-day visit of French President Emmanuel Macron to India as Chief Guest at the Republic Day celebrations on January 26.

The FAL in India will undertake the integration of the major component assemblies, avionics and mission systems, installation of electrical harnesses, hydraulic circuits, flight controls, dynamic components, fuel system and the engine. It will also do testing, qualification, and delivery of the H125 to customers in India and the region. The FAL will take 24 months to set up and deliveries of the first ‘Made in India’ H125s are expected to commence in 2026. The location of the FAL will be jointly decided by Airbus and the Tata Group.

Forward-Looking Statements

This press release may contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, including expected delivery dates. Such statements are based on current expectations and projections about our future results, prospects and opportunities and are not guarantees of future performance. Such statements will not be updated unless required by law. Actual results and performance may differ materially from those expressed or forecasted in forward-looking statements due to a number of factors, including those discussed in our filings with the Securities and Exchange Commission.