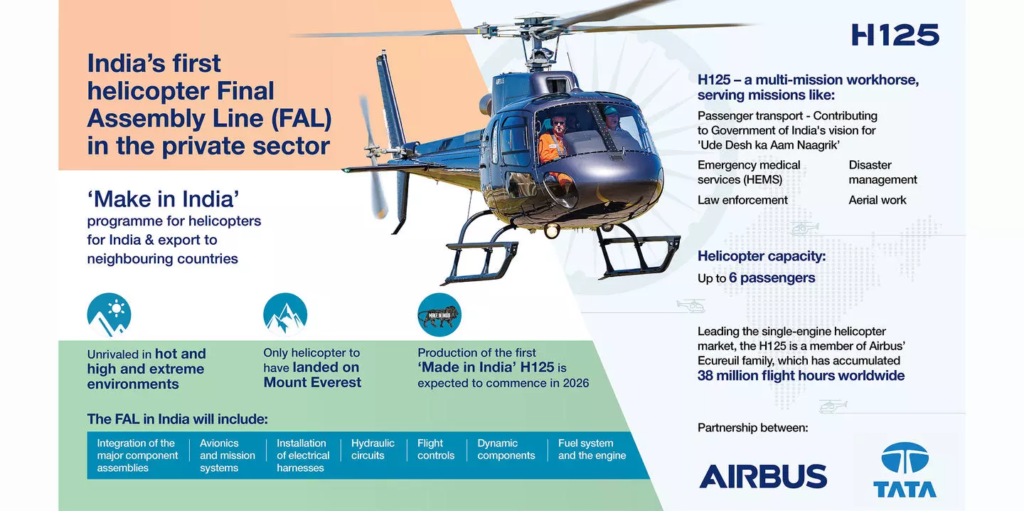

Airbus and Tata to set up first helicopter Final Assembly Line in India

New Delhi, India, January 26, 2024 - In a major boost to ‘Make in India’, Airbus Group SE (Paris: AIR) Helicopters has announced that it is partnering with the Tata Group to establish a Final…