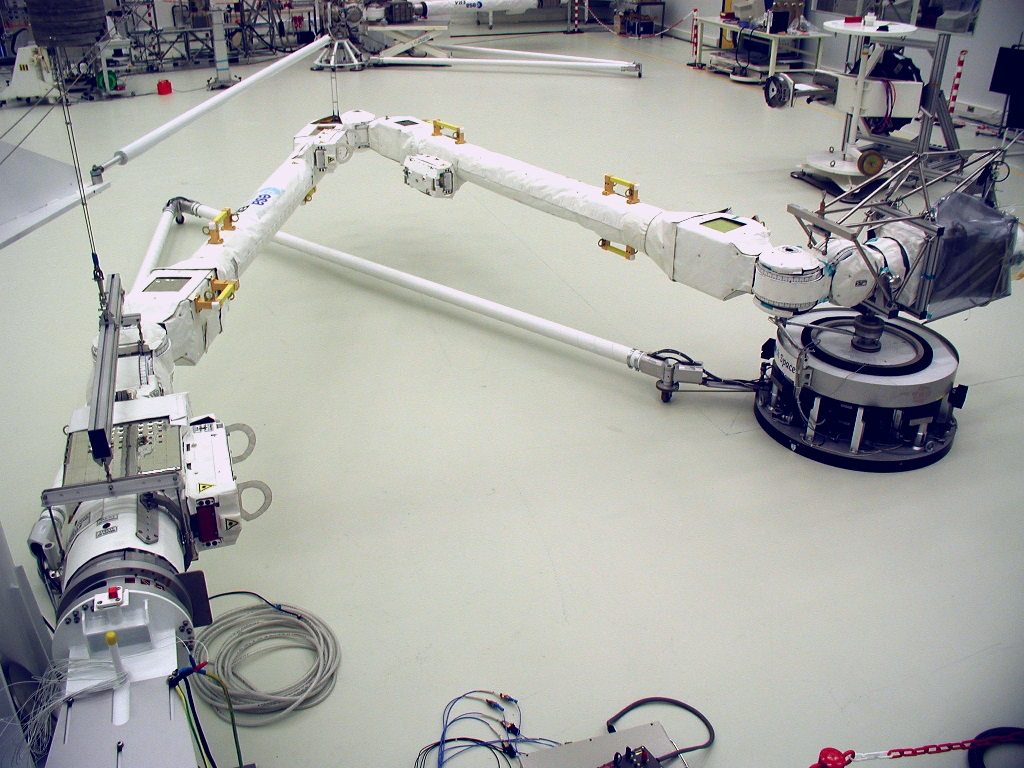

Airbus Built European Robotic Arm Ready for Space

Airbus (OTC: EADSY) space engineers have installed ESA’s European Robotic Arm (ERA) onto the Russian Multipurpose Laboratory Module (MLM) and it is now ready for its flight to the International Space Station (ISS). Together with…