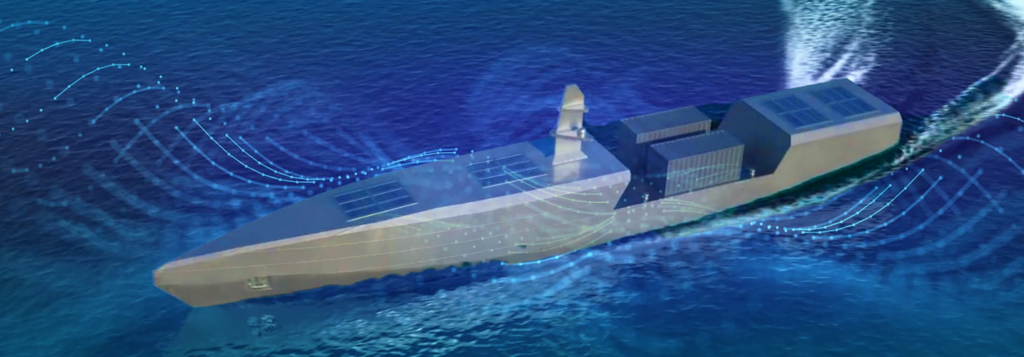

Marignane, France, October 31, 2023 – Airbus Group SE (Paris: AIR) Helicopters and Naval Group, in collaboration with the French Armament General Directorate, DGA (Direction génerale de l’armement), and the French Navy, have tested the SDAM demonstrator (Système de Drone Aérien Marine/ Naval Aerial Drone System) from a multi-mission frigate (FREMM). The trials took place on board the French Navy frigate, Provence, in the Mediterranean Sea between the 2nd and the 9th of October. The vessel had previously been adapted by Naval Group to operate the SDAM. These sea trials were arranged to demonstrate the system’s high performance from an operational warship and the SDAM’s capabilities for surveillance and intelligence missions.

The derisking study for the SDAM programme was awarded to Airbus Helicopters and Naval Group by the DGA. The objective is to design, produce and test a rotary wing unmanned aerial system demonstrator for the French Navy. The system works with the Airbus Helicopters VSR700 unmanned aerial system and the I4Drones® mission system developed by Naval Group. Naval Group has also been tasked with the integration of the system onboard military vessels. The project also involves French SMEs like Hélicoptères Guimbal and Diades, contributing to the creation of a local naval UAS industry in France.

Forward-Looking Statements

This press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, including expected delivery dates. Such statements are based on current expectations and projections about our future results, prospects and opportunities and are not guarantees of future performance. Such statements will not be updated unless required by law. Actual results and performance may differ materially from those expressed or forecasted in forward-looking statements due to a number of factors, including those discussed in our filings with the Securities and Exchange Commission.