Sao Jose Dos Campos, Brazil – July 20, 2023 – Eve Air Mobility (NYSE: EVEX) and Embraer (NYSE: ERJ) announced today that the first electric vertical take-off and landing aircraft (eVTOL) production facility will be located in the city of Taubaté, in the state of São Paulo, Brazil. Subject to the final authorities’ approval, the manufacturing plant will be situated on a designated portion of land within Embraer’s existing unit in the city that will be expanded.

The site benefits from a strategic logistical location, offering easy access via two highways and close proximity to a railroad. Another significant advantage is the region’s proximity to Embraer’s headquarters in São José dos Campos and Eve’s engineering and human resources team, which will facilitate the development and sustainability of new production processes, enhancing Eve’s agility and competitiveness.

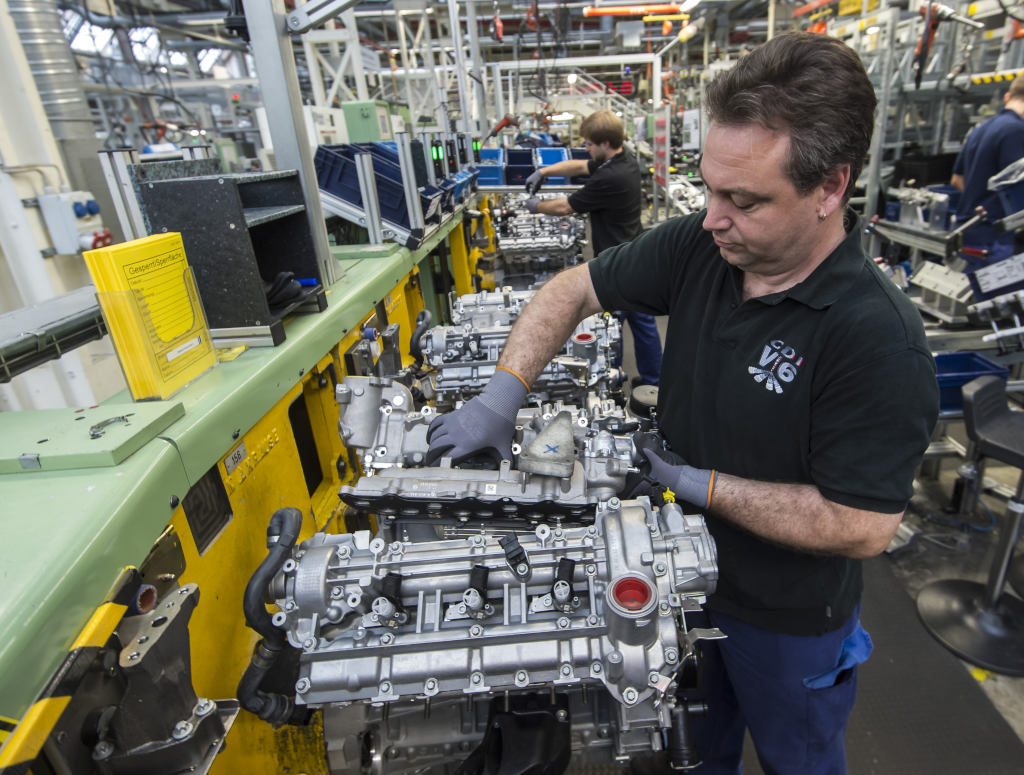

In May 2022, Eve announced a partnership with Porsche Consulting to define Eve’s eVTOL global manufacturing, supply chain and logistics macro strategy. The two companies have since worked together to research advanced manufacturing and innovation concepts and used their combined aeronautical and automotive expertise to design a concept of industrialization for eVTOL aircraft based on high safety, quality, efficiency and customer focus.

Eve continues to progress in developing its eVTOL. The company also focuses on creating a comprehensive portfolio of agnostic solutions, including a unique Urban Air Traffic Management (Urban ATM) software to optimize and scale Urban Air Mobility operations worldwide.