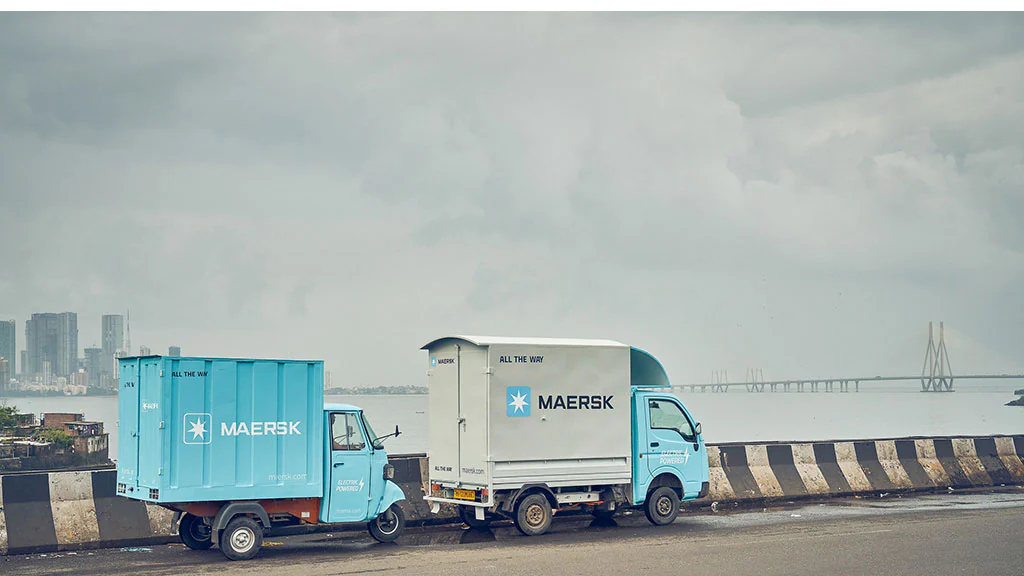

A.P. Moller-Maersk AS (OTC: AMKBY) is strengthening its omnichannel-fulfilment capabilities in Australia, with the opening of seven new facilities across the country. As the integrated container and logistics company celebrates its 30th anniversary in Australia, plans are in place to grow its already extensive operations and land-side capabilities.

The seven new facilities are being delivered over the 12 months to Q1 2024 as part of Maersk’s global integrator strategy with clear opportunities identified to expand the regional logistics landscape. This will bring the company’s total number of sites in Australia to eight in total, serviced by 550 full-time employees. Four sites opened earlier this year and three more are coming online between now and Q1 2024. Two of these facilities were integrated into the Maersk network as part of its acquisition of LF Logistics.

Maersk boasts five gateway ports and owned warehouse services in Sydney, Melbourne and Brisbane, with additional co-owned warehouse services in Perth and Adelaide. Maersk’s addition of seven facilities in Australia brings its footprint from 15,900 sqm in Q1 2023 to 142,500 sqm by end of Q1 2024, adding a total of 126,600 sqm in 12 months.

Six of the seven new sites will be omnichannel facilities, harnessing a variety of channels to interact with customers to fulfil orders. Omnichannel capabilities provide Maersk with better levels of availability and service, reduced working capital and better efficiency. It allows for an improved focus on sustainability by utilising renewable energy sources such as solar panels, smart power management systems and low energy consumption equipment.

The recent opening of Maersk’s Derrimut facility in Melbourne harnesses progressive AI technology to automate current warehousing processes. The facility caters to booming e-commerce fulfilment needs, as well as offering logistics solutions for different industries, including Footwear and Apparel, Beauty and Wellness, Healthcare, and Luxury Fashion products across Australia.

As part of Maersk’s expansion in Australia, exclusive new offerings to customers include the Flex Hub service, which enables customers to reduce warehousing costs and reduce time to market by placing products closer to their end customer markets.

The Captain Peter for reefer containers service allows customers to see the temperature inside reefer containers carrying their produce, allowing them to change it as needed, giving customers more control of how their frozen or refrigerated goods are managed while in transit with Maersk.

Forward-Looking Statements

This press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, including expected delivery dates. Such statements are based on current expectations and projections about our future results, prospects and opportunities and are not guarantees of future performance. Such statements will not be updated unless required by law. Actual results and performance may differ materially from those expressed or forecasted in forward-looking statements due to a number of factors, including those discussed in our filings with the Securities and Exchange Commission.