Magna, Utah, January 8, 2024 – Two of Northrop Grumman Corporation’s (NYSE: NOC) extended length, 63-inch-diameter Graphite Epoxy Motors (GEM 63XL) solid rocket boosters helped power the inaugural flight of United Launch Alliance’s (ULA) Vulcan Rocket and the first certification (Cert-1) mission.

- The GEM 63XL boosters are the longest monolithic, single-cast solid rocket boosters ever manufactured and flown.

- The launch represents the first flight of the GEM 63XL solid rocket boosters.

- The boosters delivered more than 900,000 pounds of thrust, nearly two-thirds of the vehicle’s total thrust at lift-off.

The Cert-1 mission carried two payloads, one that will deliver science and technology to the lunar surface, including Astrobotic’s first Peregrine Lunar Lander, Peregrine Mission One, as part of NASA’s Commercial Lunar Payload Services program and the second was Celestis’ Memorial Spaceflights deep-space Voyager mission.

Northrop Grumman began development of the fifth-generation GEM 63XL strap-on boosters in 2015, under a cooperative agreement with ULA to provide additional lift capability for the Vulcan launch vehicle. The motor was qualified for flight in 2020 via static test firing at the company’s Promontory, Utah, test facilities. In June 2022, ULA awarded Northrop Grumman a multi-year contract worth more than $2 billon for increased production of its GEM boosters, which will support Amazon’s Project Kuiper and additional ULA customers.

Northrop Grumman has supplied rocket propulsion to ULA and its heritage companies for various launch vehicles since 1964. The GEM 63XL is an extended length variation of the GEM 63 boosters, which have supported eight Atlas V launches with 27 boosters to date.

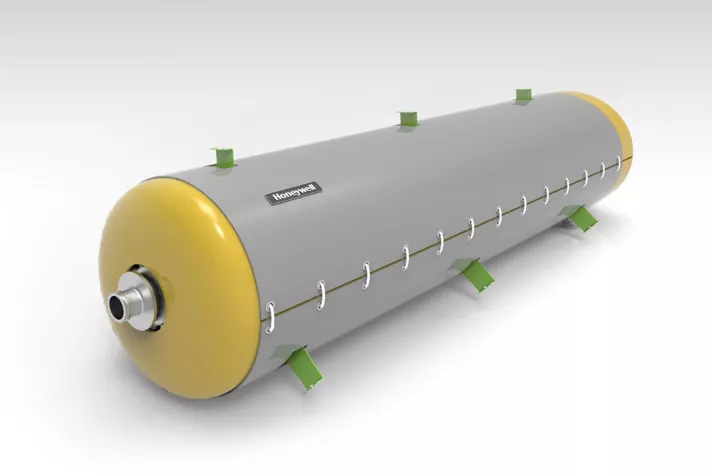

The company’s Commerce, Calif., facility also manufactured the Vulcan launch vehicle’s hydrazine diaphragm propellant tank, which feeds the Centaur upper stage Reaction Control System to provide guidance and control during the later stages of launch. This tank is a more powerful successor to the ones previously supplied by Northrop Grumman for the Atlas V and Delta IV programs.

Forward-Looking Statements

This press release may contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, including expected delivery dates. Such statements are based on current expectations and projections about our future results, prospects and opportunities and are not guarantees of future performance. Such statements will not be updated unless required by law. Actual results and performance may differ materially from those expressed or forecasted in forward-looking statements due to a number of factors, including those discussed in our filings with the Securities and Exchange Commission.