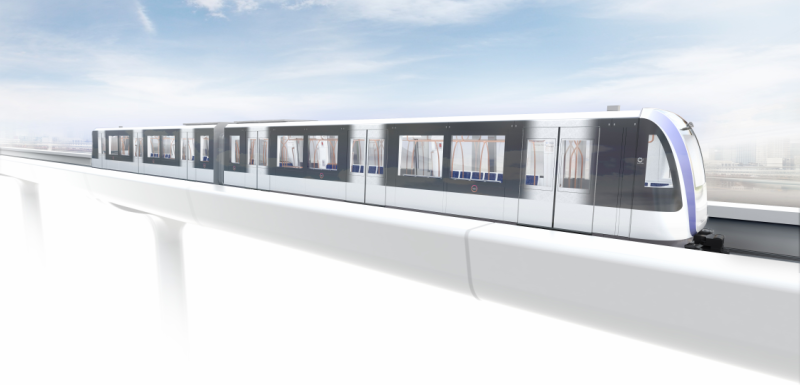

Alstom to Supply 19 Additional Metros for Line 11 of the Ile-de-France

Alstom (OTC: ALSMY) will supply 19 five-car MP14 metros with driver's cab for line 11 of the Île-de-France Mobilités network operated by RATP, for a total value of 132 million euro. This order, which is 100%…