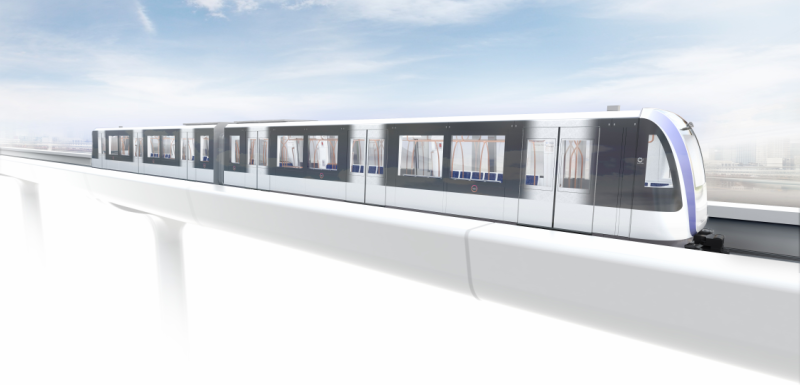

Alstom Wins Contract to Build Toulouse Metropole Third Line

Alstom has been awarded the contract by Toulouse Metropole for the system for the third and new 27 km metro line, called Toulouse Aerospace Express, for the sum of more than €470 M. The contract…