KiwiRail and Auckland Transport are already making changes to address issues raised by a report into track damage through Rolling Contact Fatigue that led to widespread speed restrictions across the Auckland rail network.

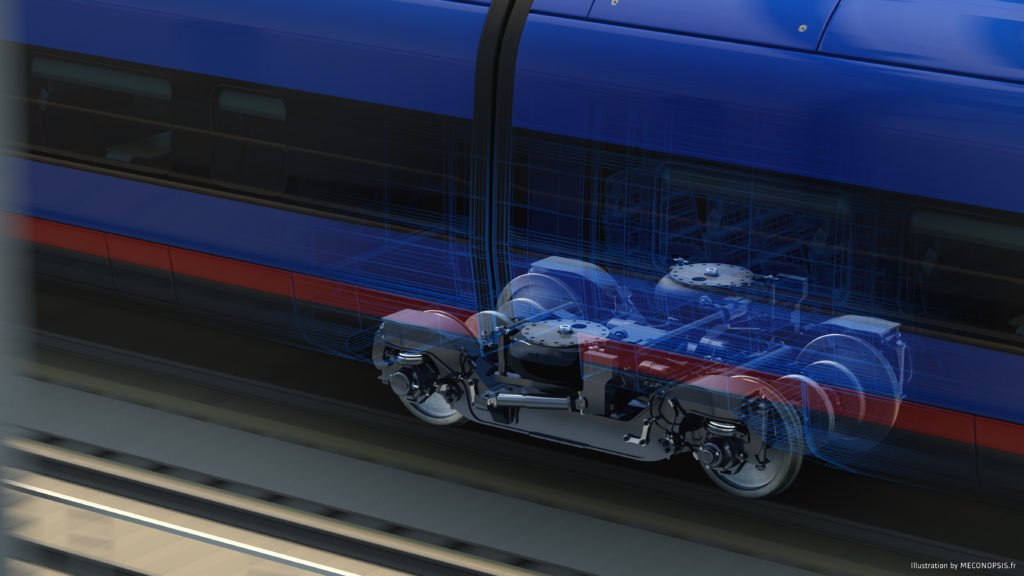

The Auckland RCF Working Group Root Cause Assessment Report, prepared for KiwiRail and Auckland Transport, identified multiple causes, with historic underinvestment in Auckland’s rail track infrastructure identified as one of the key factors. The report also pointed to insufficient rail grinding, poor underlying track condition, the design of the EMU trains and the wheel rail interface. Auckland’s climate is also another likely contributor.

KiwiRail Chief Operating Officer Todd Moyle acknowledged the report’s findings, and said work was already well advanced to implement recommendations made in the report.

Todd Moyle says that 130km of rail was replaced in just seven months and KiwiRail is now working through the second phase to repair the more complex sections of track.

The track remediation work is part of a $1.5 billion programme of work to modernise and improve the Auckland metro rail network. Other projects include the ‘third main’ project to ease congestion and allow for extra services on the busiest part of the network between Westfield and Wiri, the extension of electrification to Pukekohe, and three new stations at Drury and Paerata. When complete, Auckland commuters and freight customers will enjoy a more resilient and reliable network.