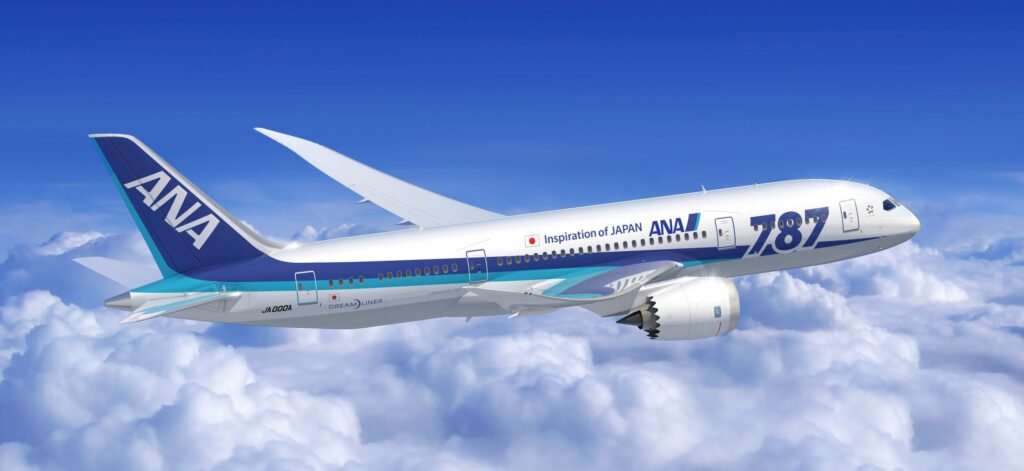

Boeing Announces Second-Quarter Deliveries

ARLINGTON, Virginia, July 11, 2023 /PRNewswire/ - The Boeing Company [NYSE: BA] announced today major program deliveries across its commercial and defense operations for the second quarter of 2023. The company will provide detailed second quarter financial…