Eve names avionics, flight controls and thermal management system suppliers

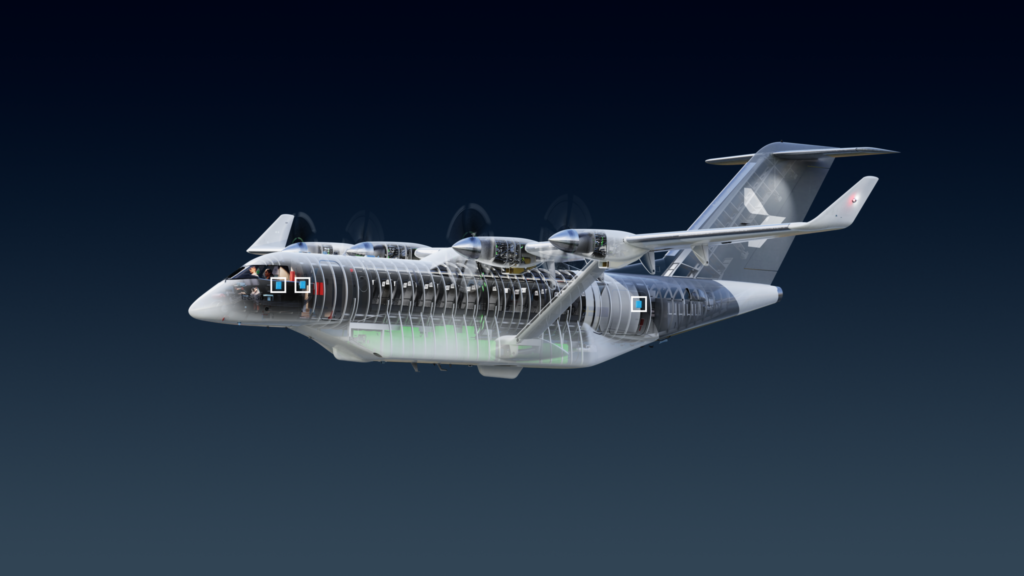

Melbourne, Florida, November 6, 2023 – Eve Air Mobility (NYSE: EVEX) named three new suppliers for its electric vertical takeoff and landing (eVTOL) aircraft. Garmin (NYSE: GRMN), will supply the avionics for the aircraft while…